Unleash your creativity with custom t-shirts for any event! Learn how to print eye-catching designs that make your occasion unforgettable and unique.

Your Guide to Printing Custom T-Shirts for Any Event

Custom T-Shirt Printing for Any Occasion: The Complete Guide to Methods, Fabrics, and Design

Turning blank tees into memorable merch, team gear, or personal statements comes down to choosing the right printing method, fabric, and artwork setup. This guide walks you through how each printing process works, why fabric and garment style matter, and how to prepare production-ready files so your designs print accurately and last. If you’re torn between photo-quality small runs and cost-efficient bulk orders, we map occasion, quantity, complexity, and material to the best approach. Read on to learn the practical strengths and limits of Direct-to-Garment (DTG), screen printing, heat transfer vinyl (HTV), dye sublimation, and Direct-to-Film (DTF); how to design with online tools; fabric trade-offs; print-on-demand workflows; and care and cost tips. Each section gives clear next steps for hobbyists and business owners alike.

What Are the Best Custom T-Shirt Printing Methods for Any Occasion?

Printing methods differ by process, price model, and ideal use case. DTG sprays water-based ink into fabric for photo-realistic prints on cotton. Screen printing pushes ink through a stencil for bold, long-lasting solids at scale. HTV applies cut vinyl heat-pressed onto garments for crisp single-color logos and numbers. Dye sublimation dyes polyester for all-over, permanent prints. DTF prints onto film, then transfers designs to many fabrics — a flexible bridge between detailed art and varied blanks. Below we outline quick pros, cons, and use cases for each method, then give a compact comparison to help you pick the right fit for your occasion and order size.

For a deeper look at how textile printing has evolved and where it’s headed, this resource covers historical techniques and recent innovations.

Advanced Textile Printing: Screen, Transfer, and Digital Inkjet Methods

Textile printing places colorants onto fabric to match a design. This chapter reviews how traditional processes have changed and surveys modern, more sustainable options — from screen and transfer printing to digital inkjet methods, cool transfer, and emerging 3D techniques.In short: DTG shines for small, photo-style jobs and multicolor art; screen printing is the cost winner for large batches and simple logos; HTV suits athletic looks and names/numbers; sublimation is best for polyester performance wear and all-over prints; and DTF works well for full-color art across different fabrics. The next sections dive into DTG and screen printing so you can compare mechanics and costs.

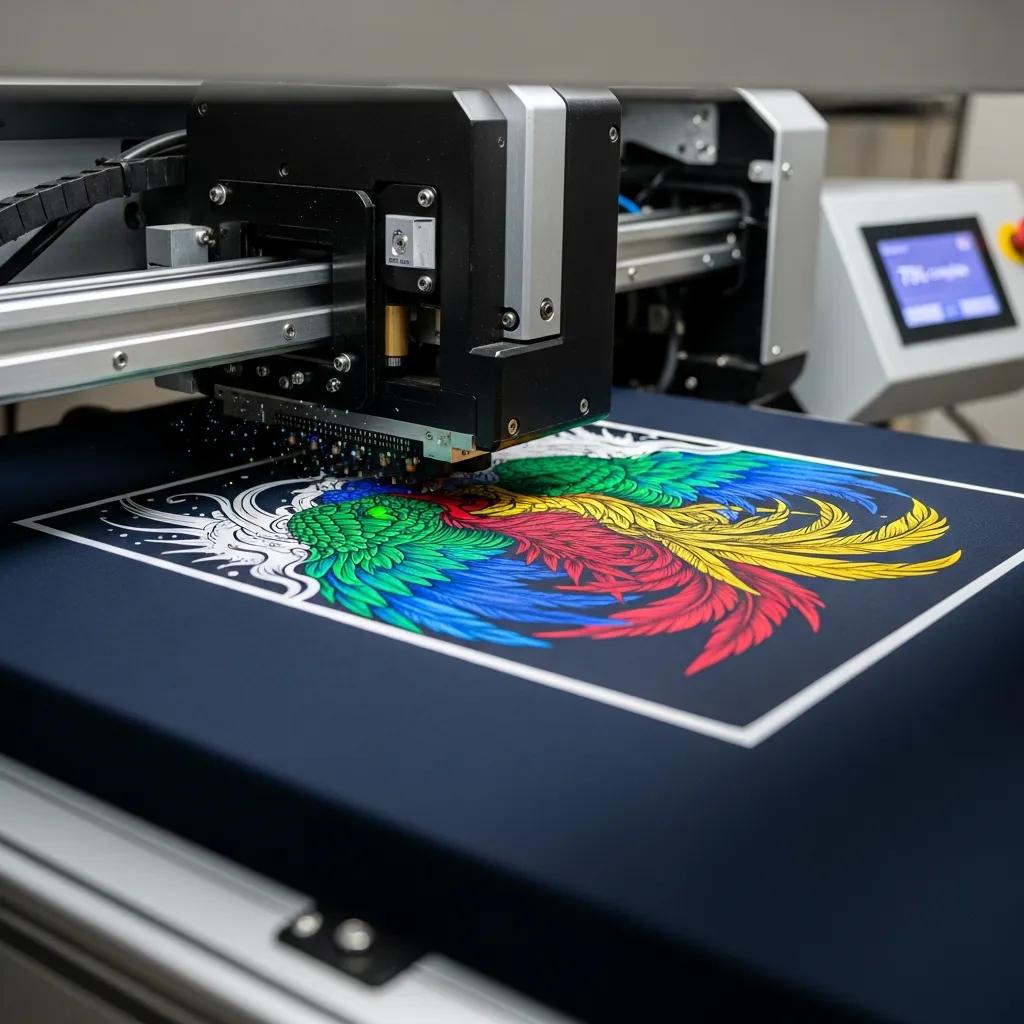

How Does Direct-to-Garment Printing Work and When Is It Ideal?

Direct-to-Garment (DTG) uses inkjet heads to spray water-based pigment into cotton fibers, producing high-resolution images with smooth gradients and fine detail. It performs best on 100% cotton or high-cotton blends because those fibers absorb ink and show vibrant colors; pre-treatment helps the ink bind and cure. DTG is ideal for one-offs or small batches with lots of colors where screen setup would be impractical. Turnaround is usually fast for low quantities, and print longevity depends on ink, pretreatment, and how garments are washed — follow manufacturer care guidelines for the best results. When volumes increase, screen printing often becomes more economical.

What Are the Advantages and Use Cases of Screen Printing for Bulk Orders?

Screen printing forces plastisol or water-based ink through a mesh stencil, layering colors for vivid, opaque coverage that holds up to repeated washing. It requires a separate screen per color, so setup costs are higher, but the per-unit price drops dramatically as quantity grows — making screen printing the go-to for team uniforms, event merch, and corporate runs. It gives excellent opacity on dark garments and strong saturation on cotton and blends. Photographic, multi-color art is less efficient at small runs, but when order sizes justify setup, screen printing is hard to beat for durability and cost per shirt.

Use this quick reference: DTG for detailed small batches, screen for low per-unit cost at scale, sublimation for polyester performance gear, and DTF or HTV when blank choice or style demands flexibility. Next, we’ll cover designing artwork that prints accurately.

How Can You Design Custom T-Shirts Online Using Swagify’s Tools?

Designing online needs the right tools: templates, upload options, mockups, and production-aware previews so what you see on screen matches the final garment. A solid workflow starts with choosing a blank and color, placing artwork with size and color controls, generating mockups for different sizes, and exporting production-ready files or ordering. Swagify helps teams and creators design, sell, and fulfill custom apparel and promo items with a studio that validates file formats and color profiles to cut down on proofing delays. Below is a short, repeatable workflow you can use every time.

Follow these steps so your design prints consistently across sizes and SKUs.

- Pick the garment style and color to check fabric contrast.

- Upload or create artwork — vector files or high-res PNGs work best.

- Position artwork using placement controls and size variants.

- Generate mockups across sizes and approve production previews.

- Choose printing method and fulfillment options before ordering.

Those steps make launching a single product or a whole line predictable. Next we outline the studio features that save time and the file prep printers expect.

What Features Does Swagify’s Online Design Studio Offer for Custom T-Shirt Creation?

A good studio accepts vector and raster uploads, offers placement templates, links color swatches to production inks, and runs automated checks for resolution or color problems before print. Mockups show how designs read on different sizes and garments, and placement controls let you fine-tune chest, sleeve, and back prints to real-world constraints. Bulk editing and variant management speed up multi-SKU projects, and production validation enforces minimum DPI and color-profile rules. Swagify combines those features with an intuitive interface so fewer files get stuck in pre-press.

How to Prepare Artwork Files for High-Quality Custom T-Shirt Prints?

Start with the right file types, resolution, and color mode for your chosen method and fabric. Supply vector PDFs or EPS for logos and line art so edges stay crisp at any size; deliver high-res PNGs (300 DPI) with transparent backgrounds for photographic or multicolor prints meant for DTG or DTF. Check color workflows — many DTG and DTF systems accept RGB, while screen printing usually needs separations or spot colors. Confirm ink types (water-based vs. plastisol), add bleed for edge-to-edge designs, and embed or outline fonts to avoid missing-type issues. These steps cut rework and improve first-run accuracy.

Good pre-press file management prevents avoidable print errors — it’s a small step that saves time and money.

Pre-Press File Management for Accurate Print Reproduction

Designers should spot common printing constraints early and prepare files accordingly. This work covers common issues like imposition, color management, image resolution, and other pre-press steps that improve reproduction accuracy and reduce production delays.Which T-Shirt Fabrics and Styles Are Best for Custom Printing?

Fabric and style shape how ink bonds, how colors appear, and how the shirt feels. Cotton soaks up water-based and plastisol inks and is ideal for DTG and screen printing. Polyester is the go-to for sublimation because the dye bonds to synthetic fibers. Blends offer a balance between comfort and printability. Garment style — crewneck, V-neck, hoodie, or tank — changes printable area and seam locations, so scale and placement must adapt. The table below maps common fabrics to recommended methods, care, and trade-offs to help you choose for any event or product line.

What Are the Benefits of Cotton and Polyester Blends for Custom T-Shirts?

Cotton offers a comfortable canvas that shows vibrant prints with DTG and screen processes. Polyester and synthetic blends excel for activewear because sublimation permanently bonds dye to the fiber, keeping prints from cracking. Cotton-poly blends strike a middle ground — better wrinkle resistance and cost with generally good print fidelity for DTF and adjusted screen processes. Washing hints differ: cotton tolerates warmer cycles but can shrink, while polyester prefers gentler washing and low-heat drying to keep colors bright.

How to Choose Between Crewneck, V-Neck, Hoodies, and Tank Tops for Your Design?

Style affects where designs sit and how they read. Crewnecks give a wide chest canvas for centered art; V-necks pull focus upward and may need smaller or offset designs; hoodies allow big front and back prints but require planning around seams and drawstrings; tank tops limit print area near straps. Consider pockets, neckline, and fabric thickness when sizing artwork — thicker fabrics can mute color; thinner knits show more texture. Adapting your layout per style keeps your look consistent across a product range.

How to Order and Sell Custom T-Shirts Without Managing Inventory?

Print-on-demand (POD) prints and ships items only after a customer orders, removing the need to hold inventory. This model fits creators, small businesses, and event teams who want low risk. Swagify supports personalized apparel and promo items and offers SwagShops and POD workflows so sellers can publish products, accept orders, and rely on fulfillment partners to print and ship directly to customers. Below is a quick comparison of core POD features entrepreneurs typically weigh.

POD minimizes upfront cost and lets you test designs — here are the core service benefits for businesses.

What Is Print-on-Demand and How Does Swagify’s SwagShops Support Entrepreneurs?

POD produces items after a customer orders, so you don’t tie up cash in inventory and you can run limited drops or try new designs. Swagify’s SwagShops combine a storefront with a fulfillment pipeline that handles production, packing, and shipping — letting you focus on design and marketing. It’s a good fit for event organizers and small brands that need scalability without warehousing, and it supports publishing SKU variants and designs with no minimums.

How Do Pricing, Minimum Order Quantities, and Fulfillment Options Affect Your Custom T-Shirt Business?

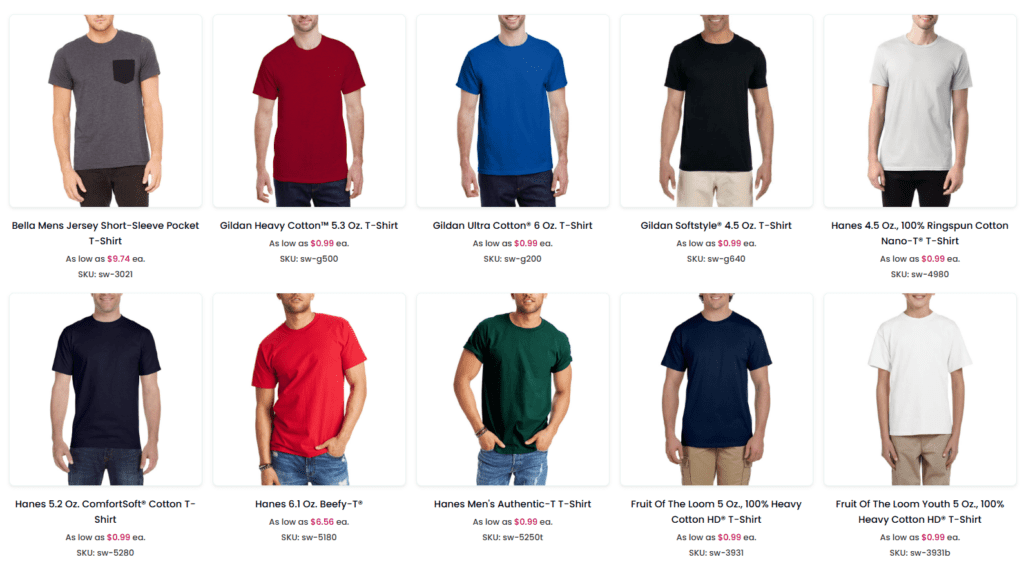

Pricing depends on per-unit print cost, setup fees (notably for screen printing), fabric choice, and shipping. Higher quantities lower per-unit cost for methods with setup fees. MOQs make screen printing attractive for bulk savings, while POD and DTG usually have no minimums, which works for on-demand sales. Fulfillment choices — in-house, third-party, or POD par tner — influence lead times, shipping cost, and margins. Faster fulfillment helps customer satisfaction but can shrink margin. To protect margins, reduce color separations, pick economical blanks like standard cotton or blends, and use POD to test seasonal or limited designs before committing to bulk orders.

What Are the Cost, Durability, and Care Considerations for Custom T-Shirt Printing?

Cost, durability, and care are linked: method and fabric set price and lifespan, and proper laundering preserves prints. Key cost drivers are print area, color count, fabric grade, and order volume — full-coverage, multicolor prints cost more, while single-color chest logos are cheapest. Durability varies: properly cured plastisol screen prints can last years; DTG life depends on pretreatment and fabric; sublimation is essentially permanent on polyester; HTV lasts with careful heat application and gentle washing. Below are practical care tips and a short recap of what affects price.

Follow these care practices to keep shirts looking great longer.

- Wash garments inside out in cold water to reduce abrasion and fading.

- Use mild detergent; avoid bleach and harsh chemicals that break down inks and fibers.

- Tumble dry low or hang dry — high heat speeds cracking and shrinkage.

- Avoid ironing directly over HTV or specialty prints; use a cloth barrier if needed.

- Fold or store shirts flat to prevent stretching that stresses print areas.

These habits lengthen garment life across printing methods and align with the longevity expectations we outline next.

How Long Do Different Printing Methods Last and How Should You Care for Custom T-Shirts?

Screen printing with plastisol typically gives the longest usable life when properly cured — it sits on the fabric and resists washout. DTG can keep good color for many washes if garments are quality cotton, pretreated, and laundered gently; lower-quality fabrics or rough care speed fading. Dye sublimation is effectively permanent on polyester because the dye becomes part of the fiber, making it ideal for activewear. HTV holds up well if applied and washed carefully, but repeated high-heat drying and heavy abrasion increase the chance of peeling. Use these lifespans to set realistic care instructions on product pages.

What Factors Influence the Cost of Custom T-Shirt Printing Services?

Final pricing is shaped by setup or screen costs, number of print colors, print area size, fabric choice, and order volume. Fixed costs like screens or separations are spread over larger orders, which is why screen printing gets cheaper per item at scale while DTG stays relatively stable for small runs. Fulfillment, packaging, and shipping add variable costs that affect the landed price and margins. POD moves those costs from inventory to per-order fulfillment. To lower prices, simplify designs, reduce color separations, choose economical blanks, and test with POD before committing to bulk runs.

How to Choose the Right Custom T-Shirt Printing Method for Your Specific Occasion?

Pick a method by following a short decision flow: define the occasion, estimate quantity, check design complexity, choose fabric preferences, and match a method to those constraints. For large corporate branding runs with solid-color logos, screen printing delivers the best cost-to-durability ratio. For event merch or varied designs in small batches, POD with DTG or DTF fits well. For multi-color, photo-quality art, DTG or DTF on compatible fabrics gives the best fidelity. Use the checklist below before requesting quotes or launching a product.

Use this quick checklist to balance budget, appearance, and function.

- Define the occasion and audience to set quality expectations.

- Estimate order volume to see if setup costs can be spread out.

- Assess design complexity (colors, gradients, full-coverage) to choose DTG/DTF vs. screen/sublimation.

- Select fabric based on wear needs (polyester for performance; cotton for everyday comfort).

- Decide between POD for no-inventory flexibility or bulk production for lower per-unit cost.

Apply this framework to the scenarios that follow, where we match methods to common occasions.

Which Printing Techniques Are Best for Corporate Branding, Events, and Personal Expression?

For corporate branding that needs consistent color across many units, screen printing is usually the best balance of cost and durability. Events and limited drops often benefit from POD workflows — DTG, DTF, or POD partners let organizers sell without inventory and handle fulfillment spikes. Personal expression and artist merch that demand detailed, multicolor, or photographic prints favor DTG or DTF for the best reproduction on compatible fabrics. Matching the technique to the occasion keeps budgets and visual goals aligned.

How Do Fabric Type and Design Complexity Affect Printing Method Selection?

If your artwork has fine gradients and lots of colors, choose DTG or DTF on compatible fabrics — they reproduce detail without extensive setup. Simple logos and spot-color artwork scale efficiently with screen printing. All-over prints or sublimation effects require polyester since the dye bonds with the fiber; cotton-based designs work best with DTG or screen printing for solid opacity. Fabric texture and thickness affect how inks sit and how sharp prints look; smoother knits yield cleaner DTG and DTF results, while heavier fabrics may need stronger inks and longer curing times. Weigh fabric and design together to pick the most cost-effective method that still looks great.

Frequently Asked Questions

What is the difference between Direct-to-Garment (DTG) and Direct-to-Film (DTF) printing?

DTG sprays water-based inks directly onto fabric, making it ideal for detailed, multicolor designs on cotton. DTF prints onto a film first, then transfers the design to a variety of fabrics, giving vibrant results on both cotton and synthetics. DTG is great for small, photo-style runs; DTF offers more substrate flexibility and scales well for a range of order sizes.

Can I use any fabric for custom t-shirt printing?

No. Different methods work best on different fabrics. Cotton is excellent for DTG and screen printing because it soaks up ink; polyester is required for dye sublimation since the dye bonds to synthetic fibers. Cotton-poly blends can work across several methods but may produce different outcomes in print quality and durability. Choose fabric based on the printing technique you plan to use.

How do I ensure my custom t-shirt design is print-ready?

Use high-resolution files (300 DPI recommended) in the correct color mode for your method. Provide vector files for logos and line art to keep edges sharp, and use high-res PNGs with transparent backgrounds for DTG or DTF photos. Confirm color mode requirements (RGB vs. spot colors), outline or embed fonts, and include bleed where designs reach edges. These checks reduce delays in production.

What are the typical turnaround times for custom t-shirt printing?

Turnaround varies by method and order size. DTG and POD orders often ship within a few days for small batches. Screen printing can take longer because of setup, with larger runs ranging from about a week to several weeks depending on volume and complexity. Always confirm lead times with your provider.

What are the care instructions for custom printed t-shirts?

Wash shirts inside out in cold water, use mild detergent, and avoid bleach. Tumble dry low or hang dry to prevent shrinking and cracking. For HTV, avoid ironing directly on the print — use a cloth barrier if needed. Following these steps extends print life and reduces returns.

How can I market my custom t-shirt designs effectively?

Use social platforms to share high-quality photos and video, run targeted ads, and partner with influencers to reach new audiences. Build a clean, easy-to-navigate store with clear product descriptions and care info. Limited-time drops and exclusive designs create urgency and help drive sales.

Conclusion

Picking the right printing method makes a big difference for how your tees look, feel, and hold up. Match design complexity, fabric choice, and order size to the printing process to hit the right balance of cost and quality. Whether you’re making a few shirts for an event or scaling a brand with POD and bulk runs, the right workflow keeps risk low and creativity high. Ready to bring your designs to life? Start experimenting with small runs or launch a SwagShop to test ideas without the inventory headache.